Building a Sustainable Future

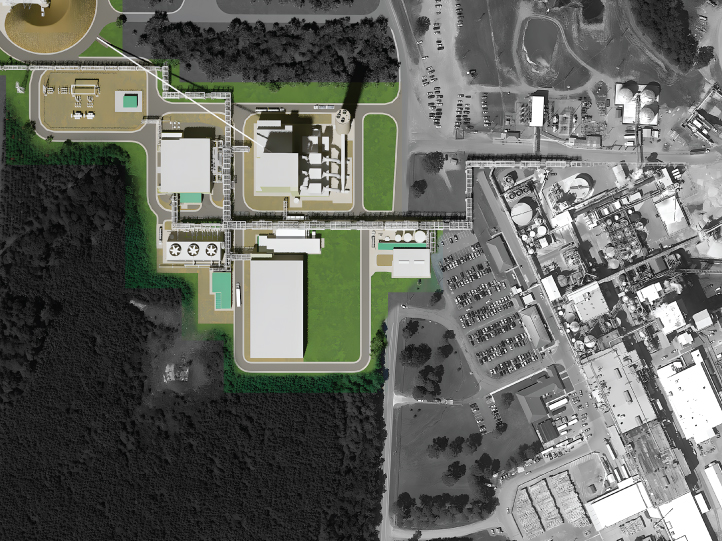

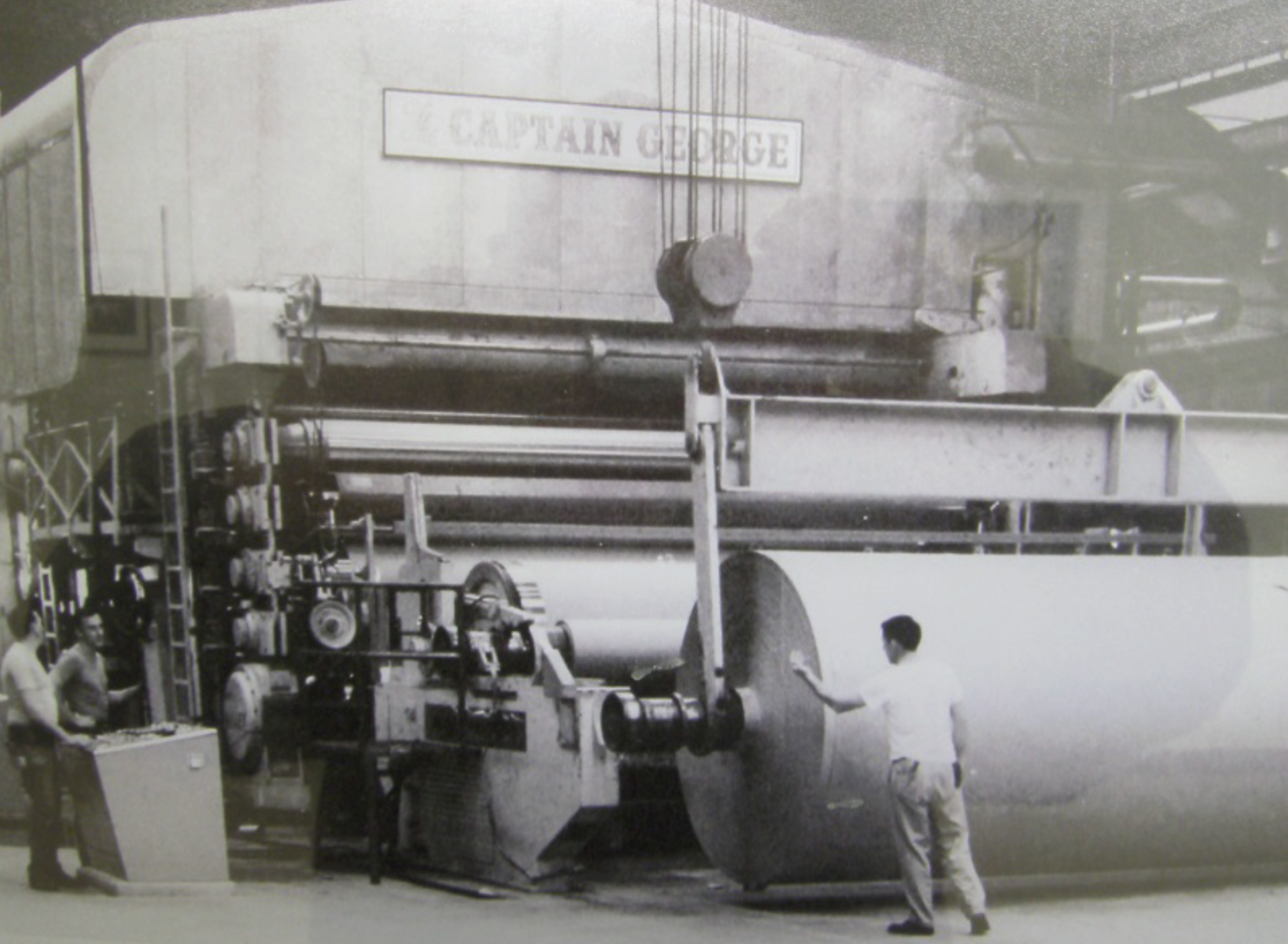

The Green Bay Packaging PowerPack Project is a bold, multi-year modernization of our Arkansas Kraft paper mill in Morrilton. This transformative investment strengthens our infrastructure, reduces greenhouse gas emissions, and positions us for a sustainable future.

About PowerPack

Project PowerPack highlights Green Bay Packaging’s dedication to innovation and sustainability. With a $1 billion investment in upgrading key manufacturing components, including the recovery and biomass boiler infrastructure, we are enhancing operations for a more sustainable future.

This initiative is part of our comprehensive decarbonization strategy, designed to significantly cut Scope 1 and 2 greenhouse gas emissions. By installing a steam-driven electric turbine generator to produce electricity, we are taking bold steps toward reducing our environmental impact while improving efficiency.

Additionally, by acquiring approximately 300 acres of land for future investments and expansions, we ensure that our mill remains viable and competitive for years. Investing in the PowerPack Project means investing in a greener planet and a thriving economy.

Investing in People

The PowerPack Project is more than an investment in infrastructure, it’s an investment in people. As we modernize and grow, we’re creating new pathways for careers, education, and community development.

Timeline

Proud Partners of Project PowerPack

Arkansas Kraft Mill Division Job Opportunities

The Arkansas Kraft Division is a leader in employee development, investing in advanced maintenance training facilities and innovative operations training programs.

Frequently Asked Questions

Q: What is the goal of the PowerPack Project

A: To modernize the Arkansas Kraft mill, reducing emissions, and prepare for future growth.

Q: Will there be job opportunities?

A: Yes! The project will create new workforce opportunities, training programs, and internships.

Q: How will this project impact the environment?

A: The project includes major upgrades like new boiler systems and an electric turbine generator, which will significantly reduce greenhouse gas emissions and improve energy efficiency.

Q: What are Scope 1 and Scope 2 greenhouse gas emissions?

A: Scope 1 emissions are direct emissions from sources owned or controlled by Green Bay Packaging, such as fuel combustion in boilers.

Scope 2 emissions are indirect emissions from the generation of purchased electricity used by the facility.

By modernizing our systems and generating more of our own electricity, the PowerPack Project will reduce both types of emissions, supporting our sustainability goals.

“To uphold our commitment to innovation and excellence, we recognize the importance of investing in future technology. These investments only happen because of our hard-working and loyal workforce and a supportive community in Morrilton, Arkansas”

– quote from Matt Szymanski, Vice President of Mill Operations, Green Bay Packaging