Paper Mill Technology

Green Bay Packaging’s mill operations are seamlessly integrated to provide our customers with world-class quality and industry-shaping ideas in environmental innovation and process technology.

Most Sustainable Paper Mill System in the U.S.

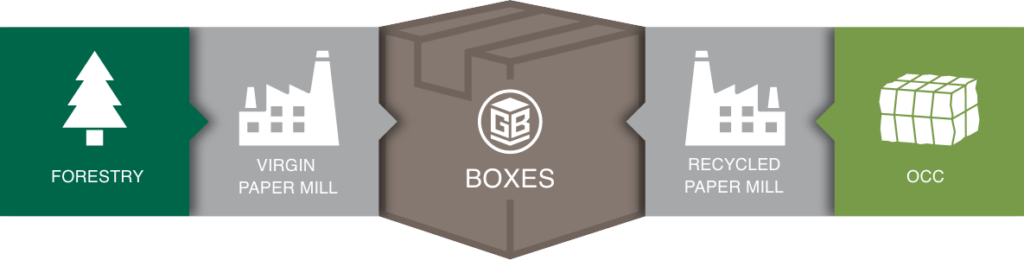

The corrugated packaging supply chain requires a steady stream of both recycled and virgin fiber to remain sustainable. Green Bay Packaging takes pride in owning timberlands and produces both virgin and recycled paper, earning us the title of Most Sustainable Paper Mill System in the United States.

Legacy of Papermaking